Many have heard of the term offshoring, moving production to another country to save on costs, but are you familiar with reshoring? Reshoring involves moving the production of goods back to the country where the business is located. There are several reasons for a company to make this decision, including new legislative or regulatory requirements; increasing costs due to changes in the country where the production was outsourced; or logistical reasons related to cost and time. While the reasons for reshoring may be varied, a strong Career Technical Education (CTE) system that prepares future workers is necessary to make reshoring possible for companies based in the United States.

There has been an increasing push within the manufacturing industry to reshore more production back to the U.S. due to recent legislation at the federal and state levels. While there have been policies regarding federal purchasing that require domestic production, such as the Defense Federal Acquisition Regulation Supplement (DFARS), the Buy American Act and recently the Build America Buy America Act, there are now new policies being enacted focused on supporting private sector domestic sourcing. The Creating Helpful Incentives to Produce Semiconductors and Science Act of 2022 (CHIPS and Science ACT) is intended to increase more domestic production of semiconductors, but also to support the growth of new and emerging technologies such as quantum computing, AI, clean energy and nanotechnology. To facilitate this growth, the CHIPS Act authorizes $174 billion over the next five years for STEM programs, workforce development and research and development (R&D).

There has been an increasing push within the manufacturing industry to reshore more production back to the U.S. due to recent legislation at the federal and state levels. While there have been policies regarding federal purchasing that require domestic production, such as the Defense Federal Acquisition Regulation Supplement (DFARS), the Buy American Act and recently the Build America Buy America Act, there are now new policies being enacted focused on supporting private sector domestic sourcing. The Creating Helpful Incentives to Produce Semiconductors and Science Act of 2022 (CHIPS and Science ACT) is intended to increase more domestic production of semiconductors, but also to support the growth of new and emerging technologies such as quantum computing, AI, clean energy and nanotechnology. To facilitate this growth, the CHIPS Act authorizes $174 billion over the next five years for STEM programs, workforce development and research and development (R&D).

National and state policy are not the only reasons for manufacturers choosing to reshore, there are also cost and supply chain reasons. As the economies of nations around the world evolve, the savings from previously lower cost of production compared to domestic production is diminishing and almost negligible in some cases. Logistical issues have also prompted the drive to bring production back to the U.S. During the coronavirus pandemic, the fragility of the supply chain and transportation infrastructures was exposed.

Supporting reshoring efforts requires access to a robust and highly skilled workforce and talent pool. This is where a high-quality CTE system that is accessible to all learners plays a critical role. Domestic manufacturing has many career pathways available to learners including those outside of what is traditionally considered as being a part of the sector. Business management, logistics, supply chain management, and many more in-demand careers are available within the umbrella of manufacturing. Learners need to have access to the education and training needed to prepare them for these in-demand career opportunities that provide self-sustaining wages.

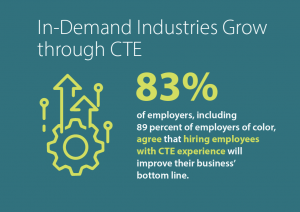

To maximize’s CTE’s value in reshoring, employers must be informed on its alignment with reshoring-connected careers and be partners in designing CTE programs to meet skills needs. Advance CTE’s employer engagement fact sheet and messaging guidelines provide several recommendations on effectively engaging employers about the positive return on investment that CTE experiences provide for business and economic growth. The findings from the research provide CTE leaders with several suggestions to enhance employer participation, program quality and learner outcomes.

To maximize’s CTE’s value in reshoring, employers must be informed on its alignment with reshoring-connected careers and be partners in designing CTE programs to meet skills needs. Advance CTE’s employer engagement fact sheet and messaging guidelines provide several recommendations on effectively engaging employers about the positive return on investment that CTE experiences provide for business and economic growth. The findings from the research provide CTE leaders with several suggestions to enhance employer participation, program quality and learner outcomes.

- Leverage partnerships to advance skills-based hiring

- Expand partnership capacity among small businesses and local systems

- Provide repeated and consistent messaging on the value and benefit of CTE for employers

This blog is the first in a series that will highlight promising state policies that connect the expansion of domestic manufacturing and CTE. The upcoming topics include curriculum and skill set development, programs of study alignment, and work-based learning programs that will all provide learners with the tools they need to be prepared to fill these high-skill, high-wage and in-demand jobs.

Paul Mattingly, Senior Policy Associate

Tags: Domestic Manufacturing, Domestic production, Employer Engagement, Federal Policy, Learner Outcomes, manufacturing, Reshoring, state policy